|

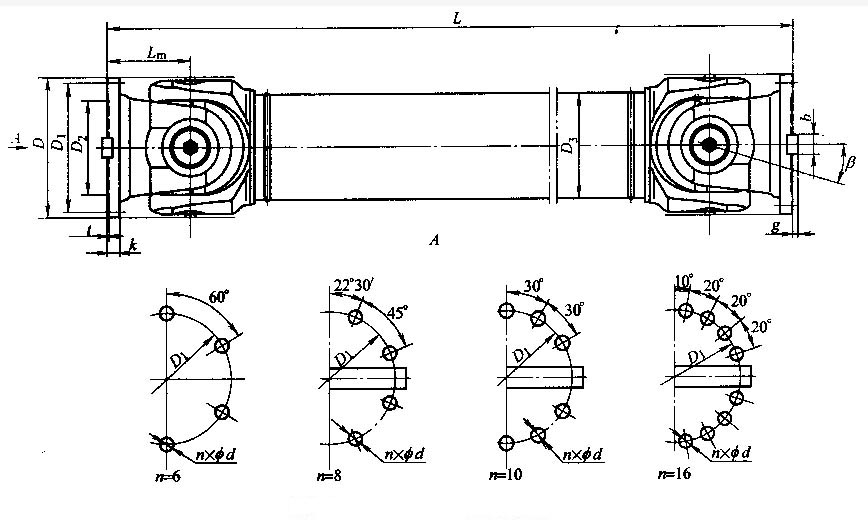

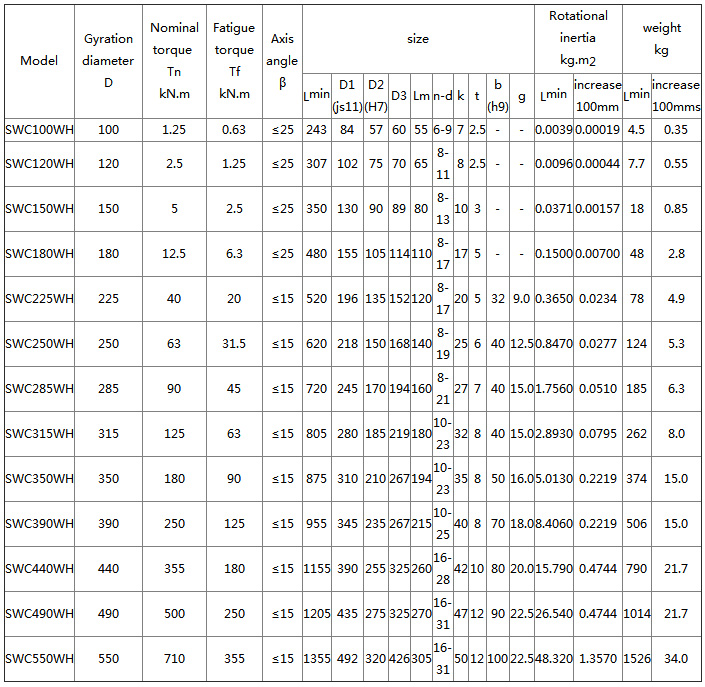

The SWC-WH short telescopic welded universal coupling is one of the most commonly used couplings. By utilizing the characteristics of the structure, it is possible to continuously rotate the two axes at different angular speeds or large axial movements without the same axis or axis, and reliably transmit torque and motion. It is widely used in the mechanical shafting of metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries to transmit torque.

BH type - standard telescopic welding type;

|

- gear coupling

- flexible coupling

- cardan shaft

- disc coupling

- jaw coupling

- grid coupling

- tyre coupling

- slider coupling

- chain coupling

- roller coupling

Mobile: 18118917615 (Manager Zhu) 13952897281 (Manager Xu)

Mobile: 18118917615 (Manager Zhu) 13952897281 (Manager Xu)Fax:0511-83993666

E-mail:sales@zjlianxin.cn

Add:No. 6, Middle Road, High-tech Industrial Park, Zhenjiang City, Jiangsu Province

cardan shaft

SWC-WH universal coupling type

SWC-WH universal coupling type

|

The SWC-WH short telescopic welded universal coupling is one of the most commonly used couplings. By utilizing the characteristics of the structure, it is possible to continuously rotate the two axes at different angular speeds or large axial movements without the same axis or axis, and reliably transmit torque and motion. It is widely used in the mechanical shafting of metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries to transmit torque.

BH type - standard telescopic welding type;

|

Copyright ? Zhenjiang Lianxin Heavy Industry Machinery Co., Ltd. All Rights Reserved . Technical Support:Erun

Add:No. 6, Middle Road, High-tech Industrial Park, Zhenjiang City, Jiangsu Province Tell:0511-83998589